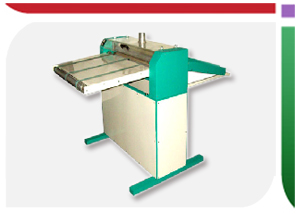

High Performance Ultra High Frequency Corona Treatment Systems

Corona treatment system is a very effective way to increase the surface tension of virtually any material. Surface treatment is required for plastic films/fabrics whose normal surface tension is not sufficiently high to permit good wetting by flexo graphic inks.

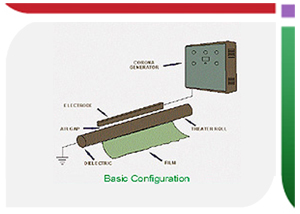

Corona treatment system increases the surface tension of the fabrics respective to inks by inducing molecular changes in the surface of the films. This is done by exposing the air at the material's surface to a high-voltage electrical discharge - a corona.

Corona discharge treatment at atmospheric pressure for improving adhesion of various polymer substrate is now standard practice.